A bill of material or a BOM is a document that contains the details of all the parts or items that are used or to be used in the manufacturing of a product. In the manufacturing world, the production of all the products involves a BOM. For this purpose, most of the manufacturing businesses create their own or use ready made bill of material templates.

A BOM contains complete details of all the items and sub-items that are used in the manufacturing of a product. Whether you manufacture clothes or an airplane, a BOM is always required. For more information, follow this article and make sure to check the given below bill of materials templates.

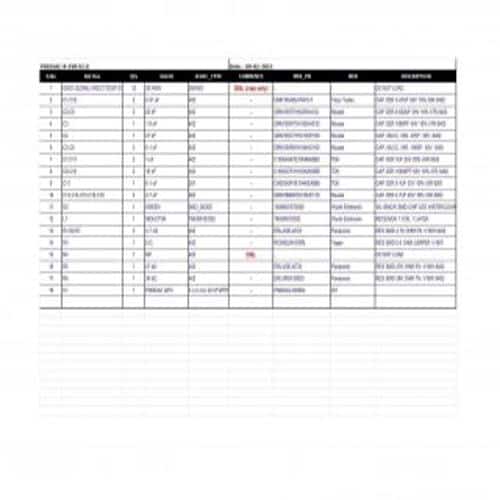

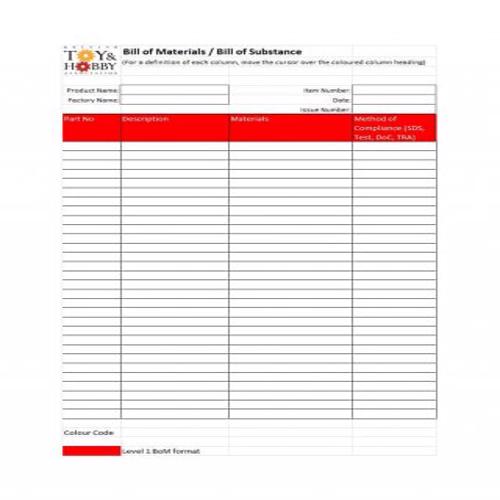

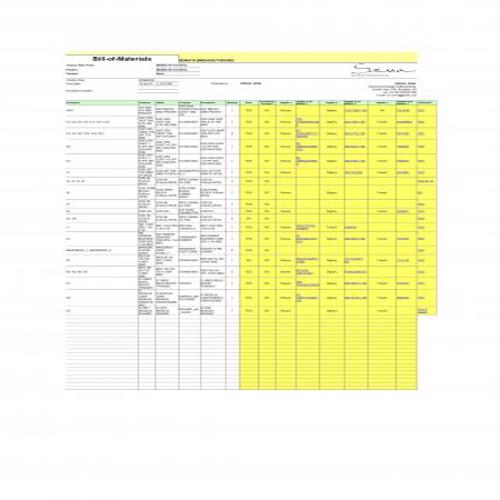

Best Bill of Materials Templates

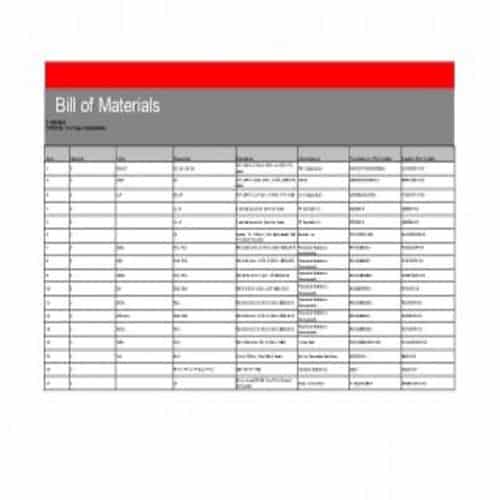

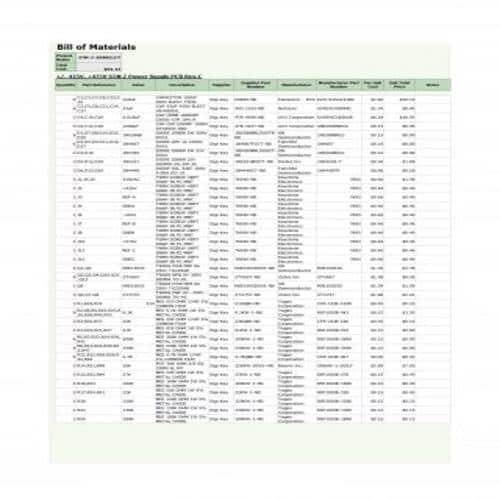

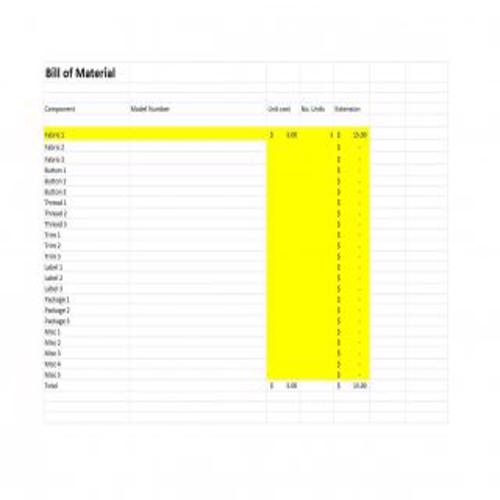

Bill of Materials Template

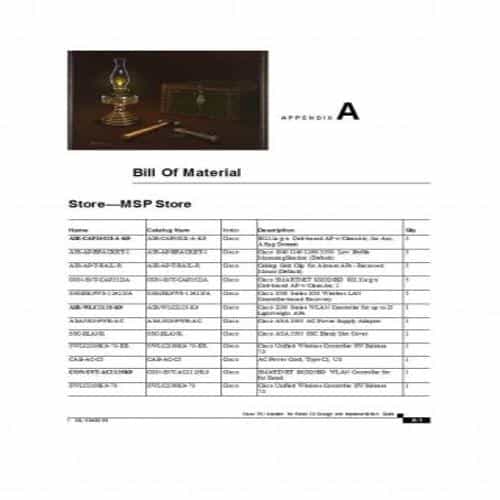

Bill of Material Template

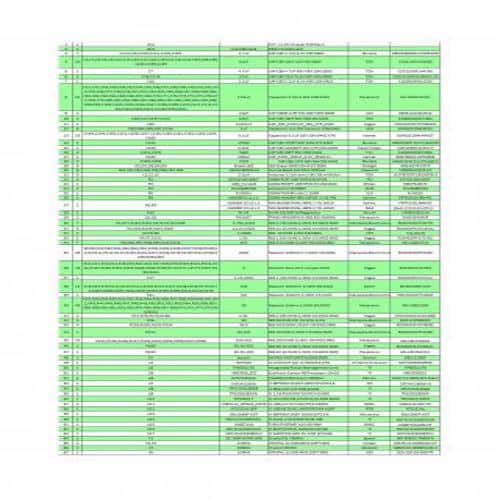

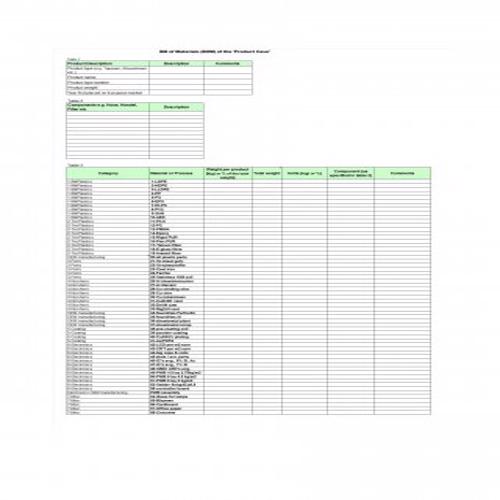

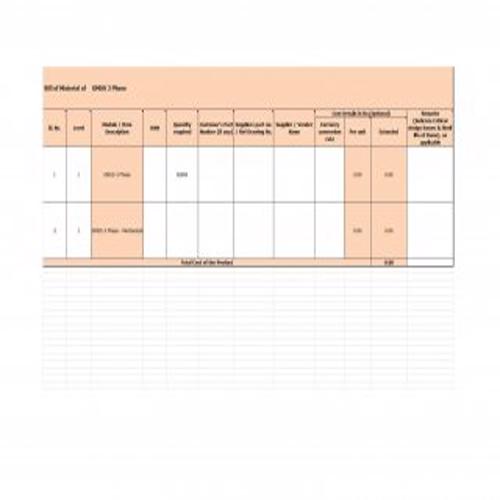

Bill of Materials Template

Bill of Material Template

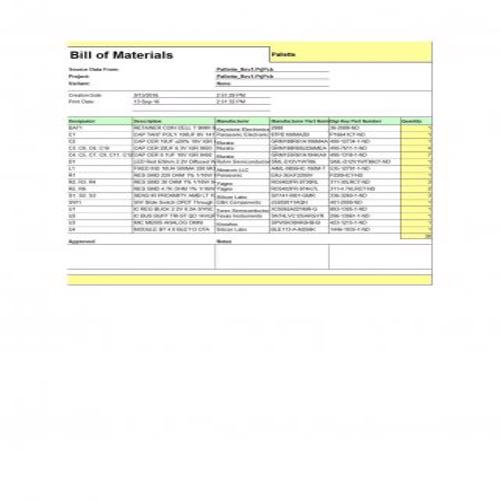

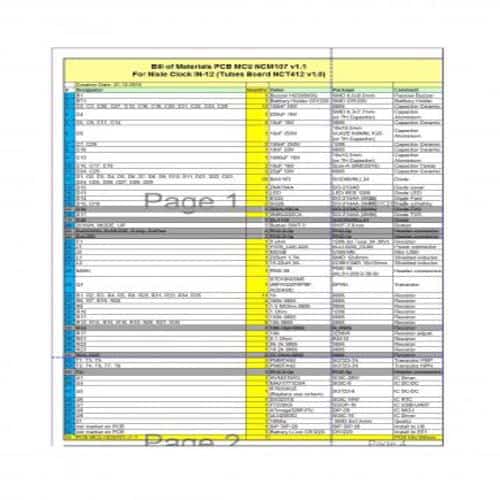

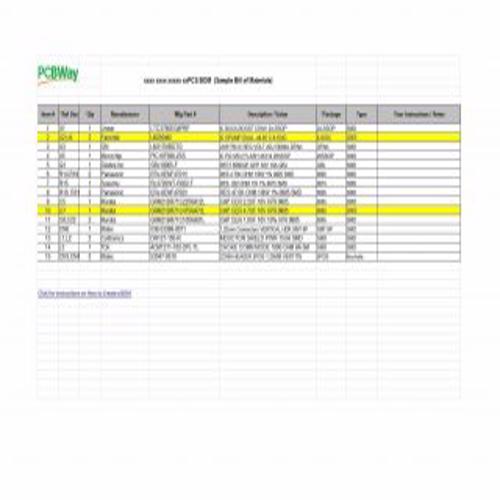

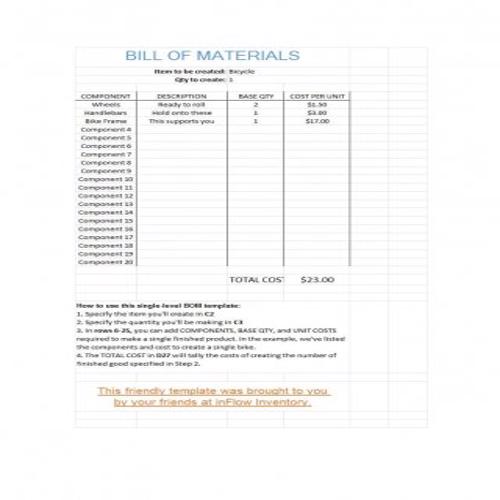

Bill of Materials Template

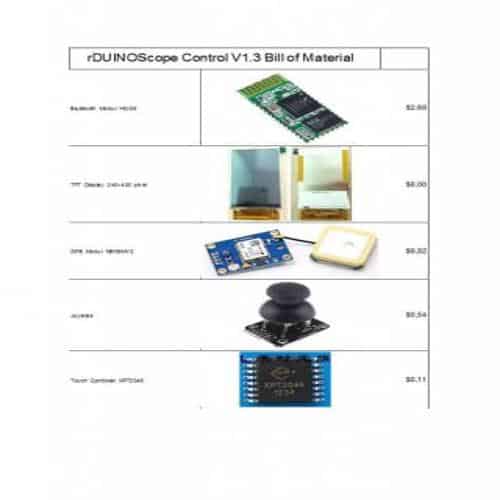

Bill of Material Template

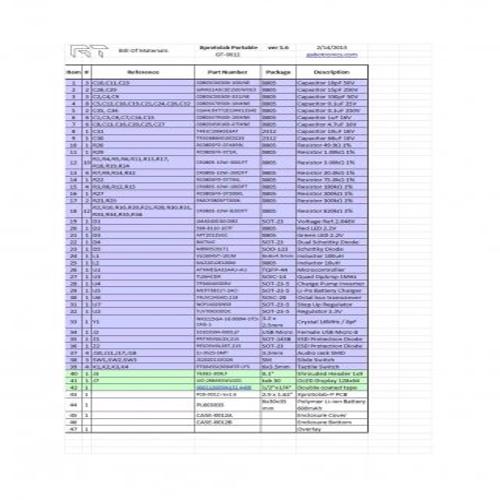

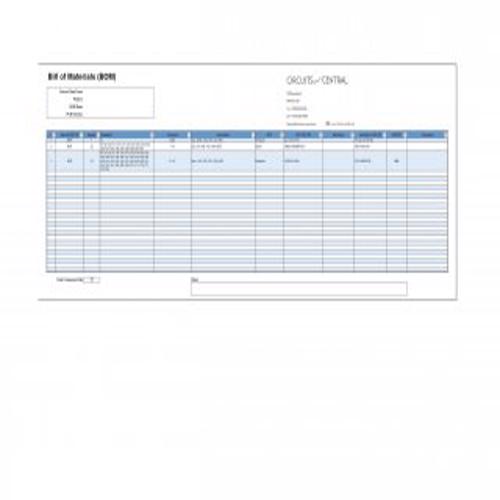

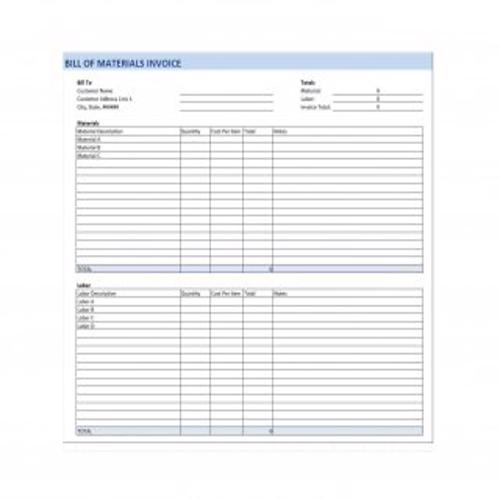

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Elements of a Standard Bill of Material Template

Following are some common elements of a standard bill of material template:

- The exact name of the each part or item that is used or to be used in manufacturing.

- A specific part number or item number which is used for reference and to avoid any confusion.

- Complete details and description of every part.

- The level, phase or stage of the production at which a particular part is used or to be used.

- A diagram or picture for each part, if possible.

- The quantity of each part.

- Per unit price for each part or item.

- The unit used for measurement.

- Name of the vendor.

- Any additional information.

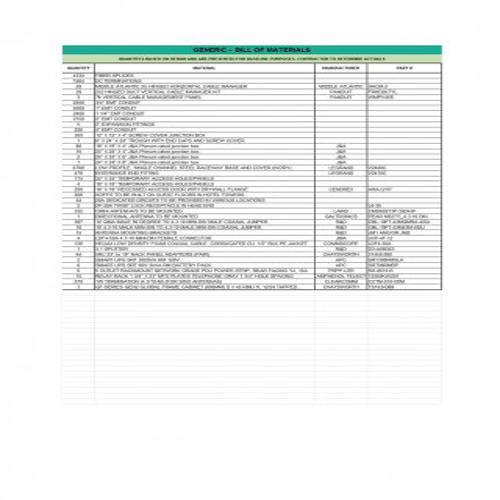

Useful Bill of Materials Templates

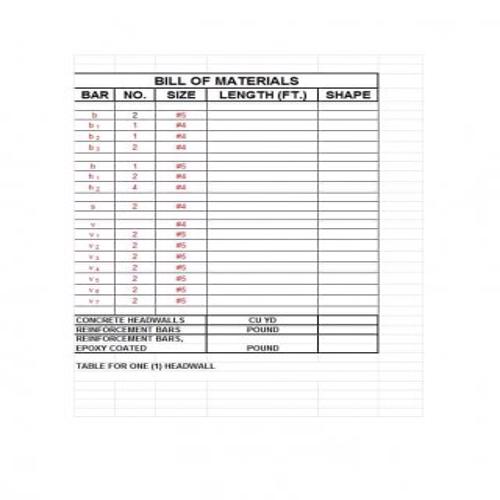

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Important things to consider in case of a BOM:

A BOM is an essential component of a manufacturing process. While preparing a BOM, following important things should always be considered:

- Always check for items that are needed to be categorized, e.g., most of the times, small items like wires, glue or any other similar items are not recorded in a BOM. This type of items are necessary to the manufacturing and so, they must be properly recorded in a BOM.

- Make sure to attach all the necessary documents with your BOM. These documents usually include the designs, drawings and instructions manual etc.

- Don’t forget to consider the users of the BOM. Make sure that all the necessary details are provided in a BOm, for its users.

- Make sure to make necessary changes in your BOM consistently, and update such changes. It is important to note that these changes can be made before production commences i.e., during the design phase. Every user of the BOM must know about any such changes. This is to make sure that everyone is using the updated version of the BOM.

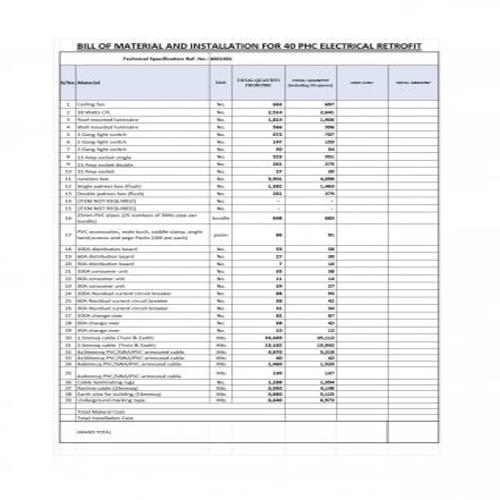

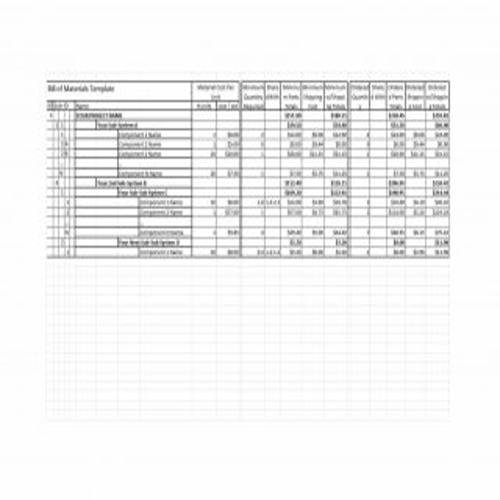

More Bill of Materials Templates

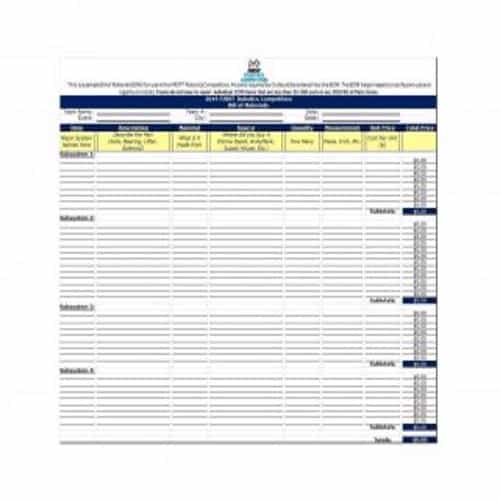

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Bill of Material Template

Bill of Materials Template

Benefits of using a BOM:

Some benefits of using a BOM are mentioned below:

- A BOM contains a complete list and details of the materials, items and sub-items that will be used in a manufacturing process, thus performing the complete process effectively and efficiently.

- A BOM ensures flexibility and adaptability in the manufacturing process.

- A BOM enhances the internal communication between the different departments engaged in the manufacturing process.

- It ensures accurate management of the resources, thus avoiding abnormal wastages.

- A BOM is quite helpful when it comes to creating homogenous products in the future.

- A BOM allows effective decision making regarding the manufacturing of a product.

- A BOM keeps proper track of inventory levels.